We’ve been working in collaboration with Olaf Diegal and his team at Auckland University to print this valve block for a hydraulic system.

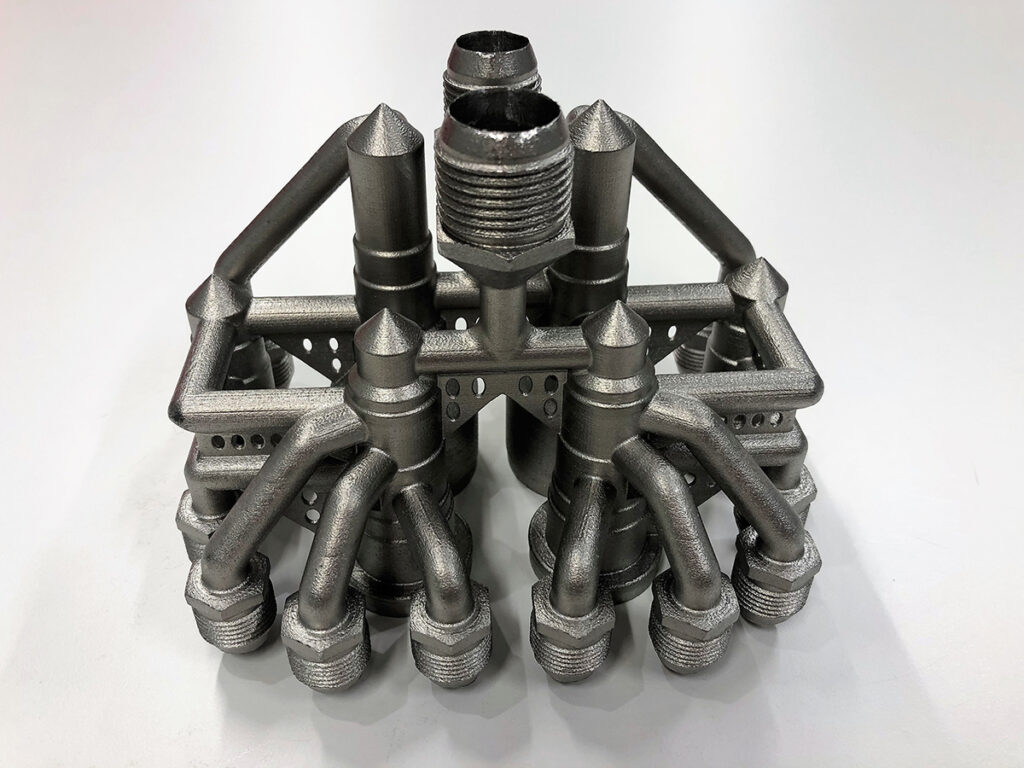

Every now and then we are asked to print a part that simply blows us away in terms of how well it has printed and this valve block is so suited to metal 3D printing. Organic shapes, non-uniform sections and hollow areas become possible, leading to a part that is optimised for function and cost using additive manufacturing.

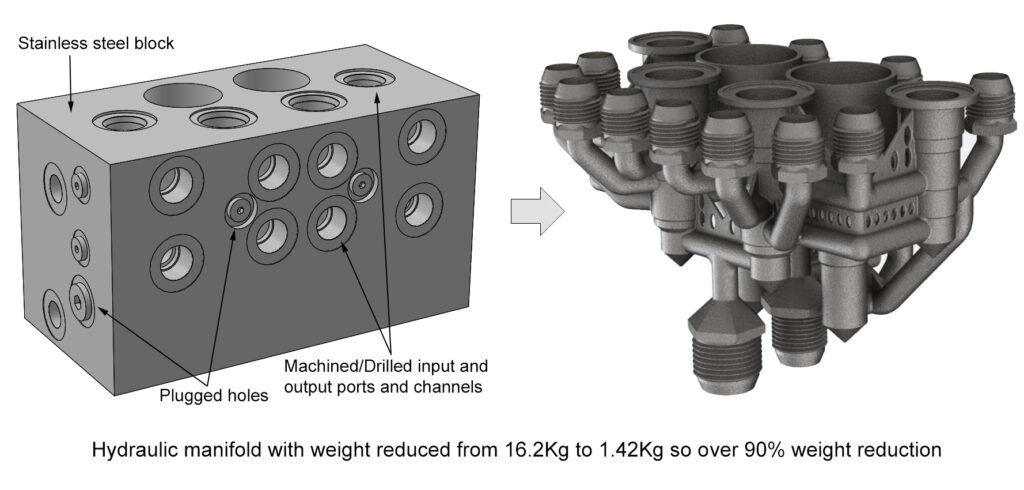

The ‘before’ picture (on the left) shows how the part was previously manufactured; the university team machined one of the blocks out of steel.

The ‘after’ picture (on the right) shows the Stainless Steel 316L manifold printed by us.

We’ve been working in collaboration with Olaf Diegal and his team at Auckland University to print this valve block for a hydraulic system.

Every now and then we are asked to print a part that simply blows us away in terms of how well it has printed and this valve block is so suited to metal 3D printing. Organic shapes, non-uniform sections and hollow areas become possible, leading to a part that is optimised for function and cost using additive manufacturing.

The ‘before’ picture (on the left) shows how the part was previously manufactured; the university team machined one of the blocks out of steel.

The ‘after’ picture (on the right) shows the Stainless Steel 316L manifold printed by us.

The question is, why would you 3D print this as opposed to machining this part?

The weight of the 3D printed part is 1.42kg compared to the machined part which weighed 16.2kg, so an overall weight reduction of 90%.

3D printing this manifold has resulted in reduced pressure losses caused by tight angles and has overall greatly improved the flow dynamic at no extra cost.