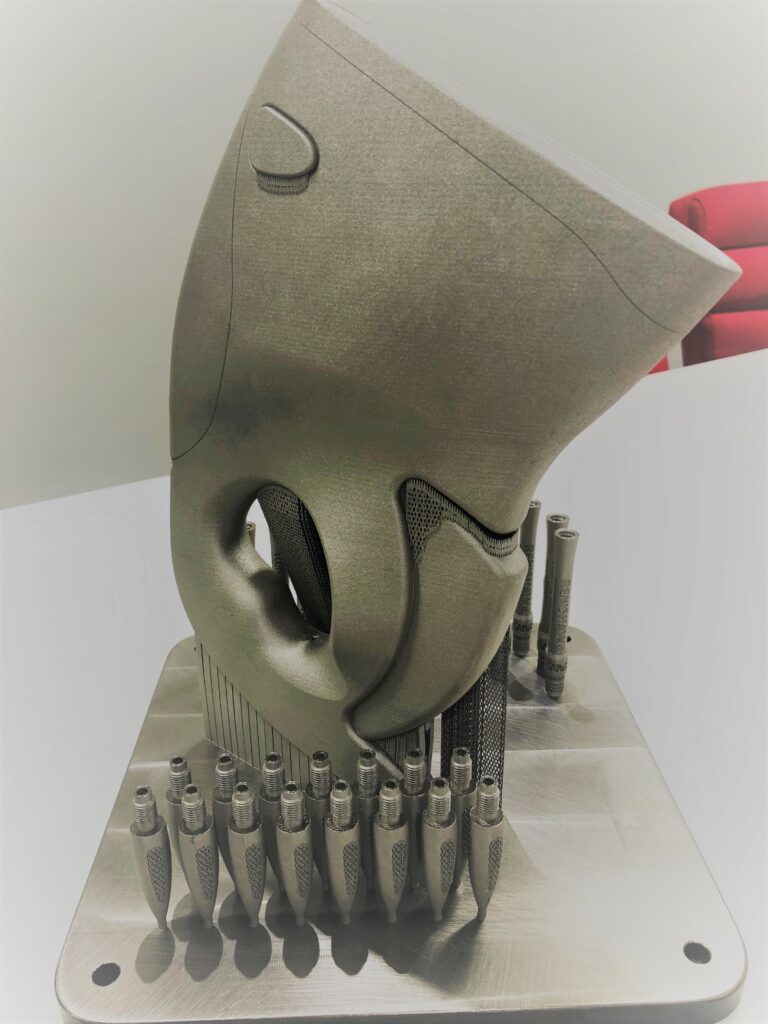

One of the best ways to reduce mass without reducing too much structural integrity, is to add a lattice structure. The benefit of using a lattice over simply hollowing a part, is the lattice does not require internal support. When designed correctly, it can maintain good strength and performance.

We can create a simple uniform wall thickness internal lattice structure using our Netfabb build software. This is great for those non-structural parts where you need the mass removed but need to maintain that solid look.

For more structural parts, where a uniform wall thickness does not suit (where you have threads, structural ribs or require post machining), we require separate internal and external models. This can be done two ways.

Method 1: We require to to add a lattice to your part: Two solid models; one of the main body and one of the internal body, that is going to be turned into lattice.

The internal body will need to be modelled to allow for the thickened or internal features. This is then subtracted from the outer solid model via a Boolean op leaving a cavity. Holes will then be added to the shell for powder removal. The internal solid model is then turned into a lattice structure in our Netfabb build software and merged with the outer shell creating the complete part.

Method 2: Our clients can supply the main outer shelled part with various thickened features as well as specific openings for powder removal. We still require the solid internal model to form the lattice as per the first option.

When providing parts for latticing, A quick tip is to have both models labelled to differentiate between internal/lattice and outer/shell. Both models must line up perfectly, so base both models off the same part where possible.