Metal 3D Printing for Industrial

Metal 3D printing has been playing an essential part with industrial manufacturers for several years and we have been collaborating with Backlanz in the consumer goods sector. Backlanz have designed a unique detachable lightweight bipod for hunters that is half the weight of a standard hunting bipod.

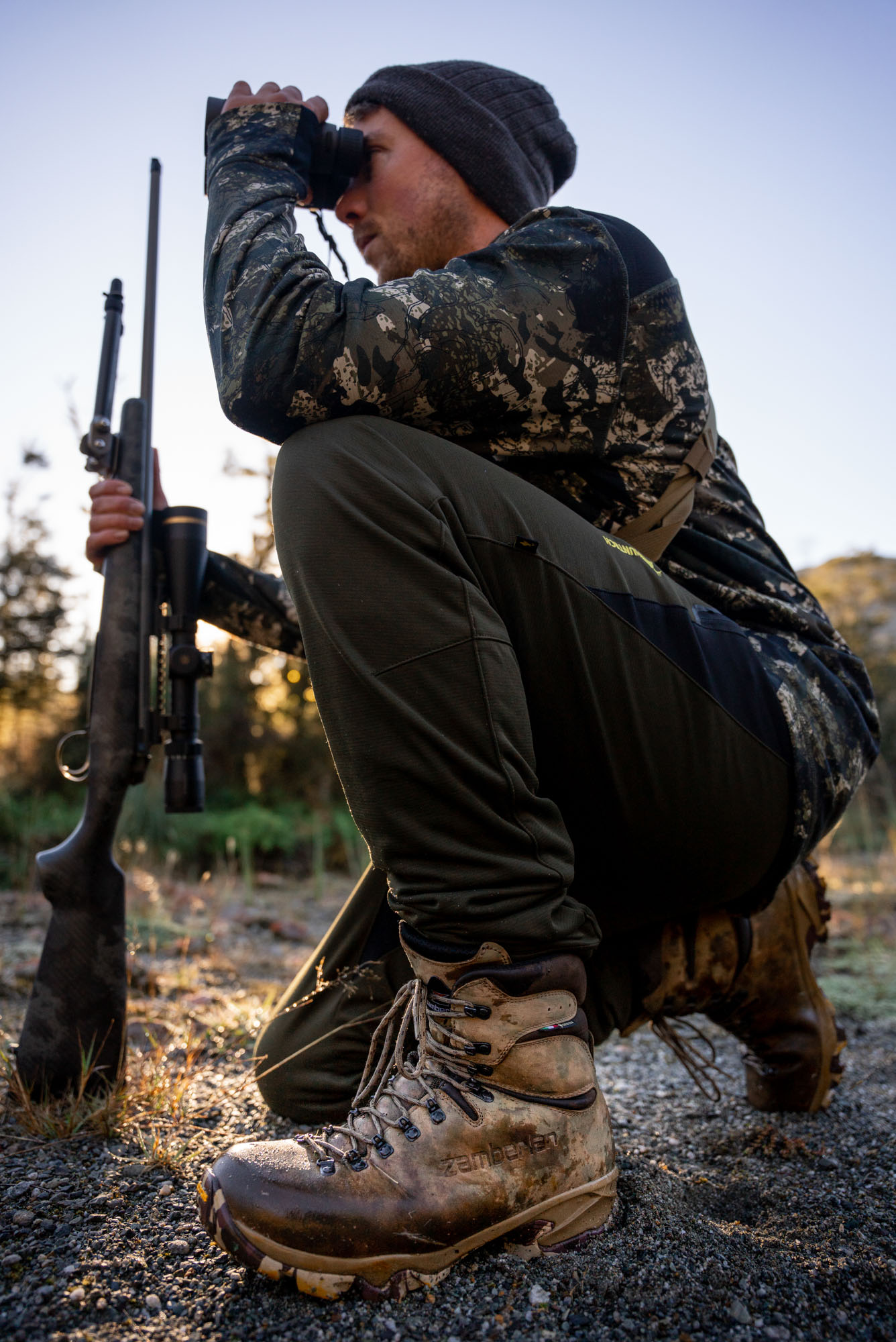

The best ideas often come from a passion for a sport and Ethan, an engineer and owner of Backlanz, is an avid hunter and has spent many hours in the great outdoors. He wanted to redesign a bipod to make it easy to attach to a rifle and also to be detachable.

We helped make this dream a reality and worked closely with him to refine his design and after numerous prototypes in titanium and stainless steel, he has a remarkably successful product. His metal of choice is now Ti64 because it is incredibly light, has good tensile strength, and excellent resistance to corrosion.

CASE STUDY

Backlanz

Ethan Todd, owner of Backlanz, is a full-time engineer with a passion for hunting and the outdoor life.

The idea for his innovative bipod came from the hunting equipment he was using at the time. Frustrated with his current bipod that was too hard to put on and take off and was fixed permanently to the end of his gun. With his desire to lighten the load of his pack and make it easy to install, he decided to design his own.

The result is a unique detachable lightweight bipod for hunters that is half the weight of a standard hunting bipod.

Back in 2018, Ethan started working with RAM3D to 3D print stainless steel parts for his first prototype. New to metal 3D printing, he didn’t understand the process as he was used to designing for CNC machining. After printing his first prototype and further communication with the RAM3D team, he did some more work on his design. He was advised by adding a lattice it would make the part easier to print without distortions, also making it lighter and more cost effective.

Ethan’s first two prototypes were printed in Stainless Steel 15-5ph and 316L. After more design iterations and prototyping, his bipod parts are now printed in Titanium 64 as he prefers the finish and the lightness of them.

Currently Backlanz has a range of four different bipods with different functions to suit the most avid hunter. All are designed to be light weight, easy to install and can fold up and easily attached/detached on a rifle. All are constructed with high quality titanium parts and carbon fibre.

For the past year Ethan and RAM3D have been developing the Backlanz Tripod and this will be launched in 2023. The tripod has been designed for hunters and photographers. It has been tested by some industry leaders and their feedback has been extremely positive. Similar to the bipod, it is lightweight and utilises Backlanz’s quick detach system.

The Backlanz bipods are in full production and RAM3D has developed a system where they have set up specific printing plates for the metal 3D printing of Ethan’s parts that are printed monthly.

The titanium parts that RAM3D print for Backlanz, in Ethan’s words, “have a great surface finish and require very little post processing apart from drilling all holes out”. This is important when he is assembling his range of bipods.

We asked Ethan where most of his customers come from. He answered mostly New Zealand and Australia. He is keen to move his products into a global market and realises that will take more time. Currently he is in discussions with a number of distribution companies in Australia and the USA.

In Ethan’s words “being an engineer, I decided to put my skills to use and make my goal become a reality.”

Quote from Ethan Todd – Director, Backlanz

"Working with RAM3D given us our competitive edge. We can now design and manufacture products that outperform the rest at a fraction of the weight."