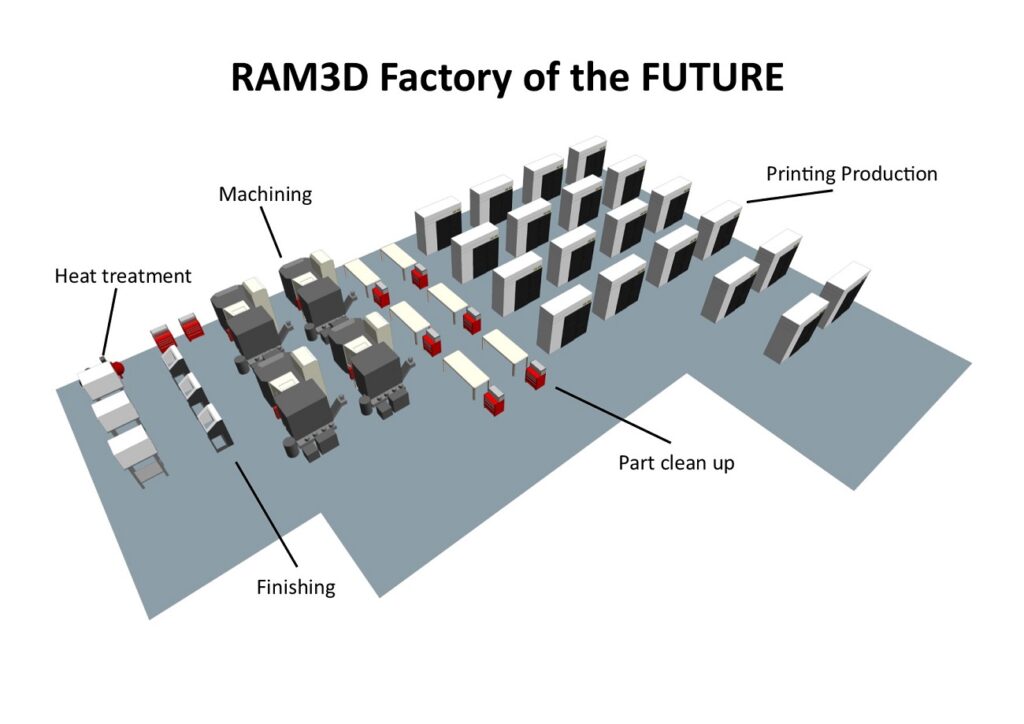

When we moved into our new premises in 2016, we had a vision of what we wanted to accomplish. To provide a state-of-the-art metal 3D printing service offering advice on design, prototyping and full-scale production.

Back then, we had just four additive manufacturing (AM) machines

Over the next number of years we had to contend with a seismic shift from low volume prototyping to large scale production. This of course was a good problem to have but we needed to respond to this customer demand and ramped up our manufacturing capacity. The other thing we had to do was maintain our process of perfect consistency in part quality, irrespective of the parts complexity metal material and volume.

In 2016 our fleet of machines consisted of three Renishaw AM systems and one SLM. The Renishaw machines offered us the flexibility, openness and easy set up that we were looking for. We had our own ideas about what we wanted to do in terms of optimising our manufacturing process, and these machines gave us the freedom to implement them.

Partnering with Renishaw has allowed us to respond to anticipated customer needs by following a phased roll out of additional metal 3D printing machines over the last eight years.

The new year 2024 brings another machine to our fleet; this is our twelfth additive manufacturing machine. The RAM3D team are extremely excited as this is our first four laser setup (4 x 500W lasers) instead of our usual single laser . Our new metal 3D printing machine is a RenAM 500Q and is known for its high-volume production and versatility.

It will be commissioned in the next couple of weeks, and we can’t wait to see what it can do! We’re keen to see how it performs with our low angle no support prints, including the zero support low angle domes.

Our factory of the future is getting closer to our dreams with machine thirteen arriving at the end of February, only another seven to go until we reach our vision!