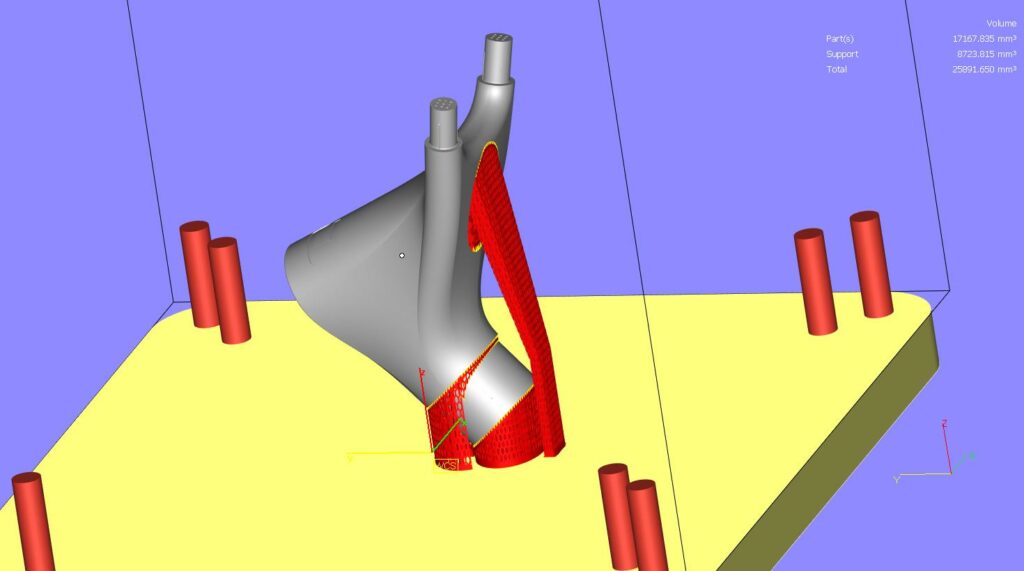

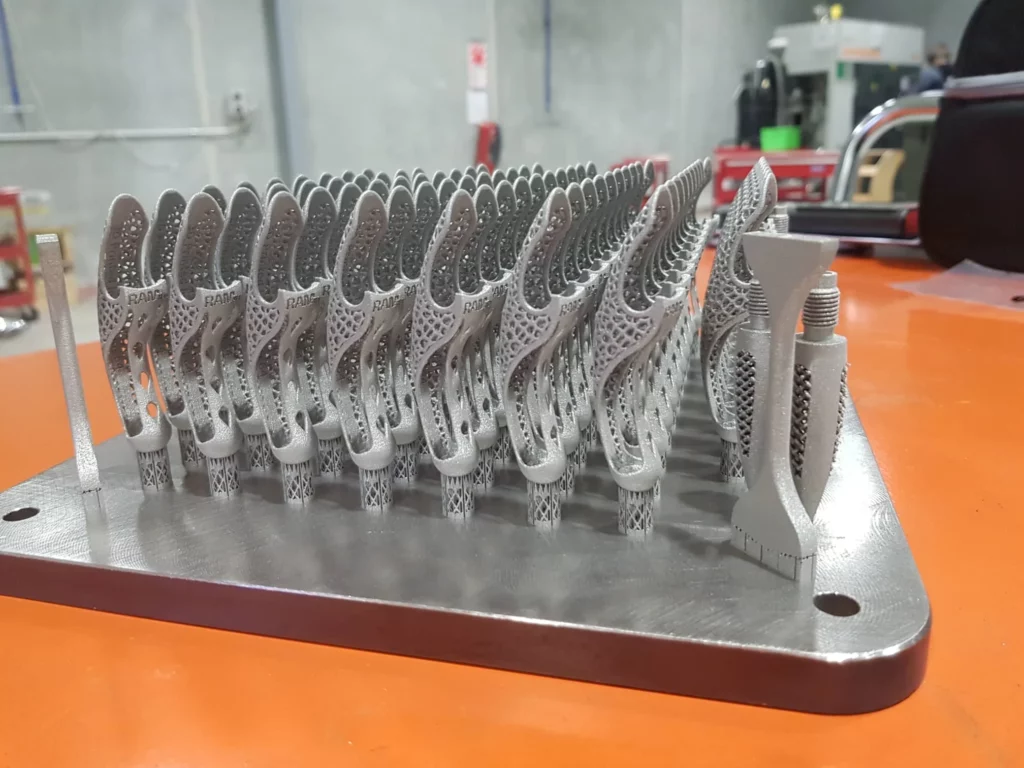

When designing your part, keep in mind what way it needs to be orientated on the build plate. Not only will this help the part to build, it will reduce the need for support structures, post processing and provide you with a better part.

Most people assume their part will be built with the most mass flat to the build plate. This often results in a failed build due to excessive stress build up. It also requires heavy support to hold it down to the plate.

When orientating a part for metal 3D printing it pays to look for the orientation with the least amount of sectional area focused in any one area. Take a T-shaped part for example; often a part like this will be more successfully printed orientated like an X.

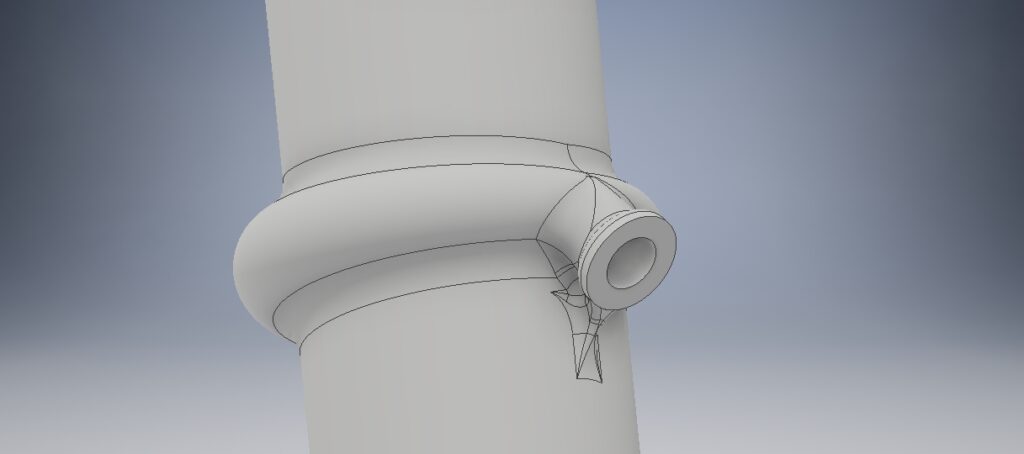

Tubes and cylinders build best in the Z axis direction; if they are 90 degrees to the build plate they require a lot of support to avoid printing out of round. In situations where this cannot be avoided, discs can be added to the model to help hold the shape.

Once you have found your part orientation, avoid sudden steps, changes in mass and downward facing angles. This is often hard to do with flanges etc, but with a bit of thinking outside the box, it can be done without requiring a lot of support. Question your design, do you need flanges or ports at 90 degrees or can they be angled? Does the flange need to be solid or a constant surface?

Curves, cones, spheres, fillets and organic shapes generally work well with additive manufacturing. This is due to less dramatic change in shape, which usually reduces stress during the part build. Large flat surfaces and thin unsupported sections tend to warp and buckle. Where a large flat surface cannot be avoided, add ribs or lattice to act as a brace.

Surfaces under 45 degrees may need support, so to keep a clean looking part, design with this in mind.

If you have any questions regarding your design and especially build and orientation of your parts, please email us on info@ram3d.co.nz or call us on +64 7 557 0344