This project is a combined effort by doctor, Andrew Robinson, from Lakes District Health Board in Rotorua, Kilwell Fibretube Engineering Rotorua (who have been involved in reverse engineering and prototyping) and us at RAM3D (who have successfully redesigned the valve and will be full-scale manufacturing the part).

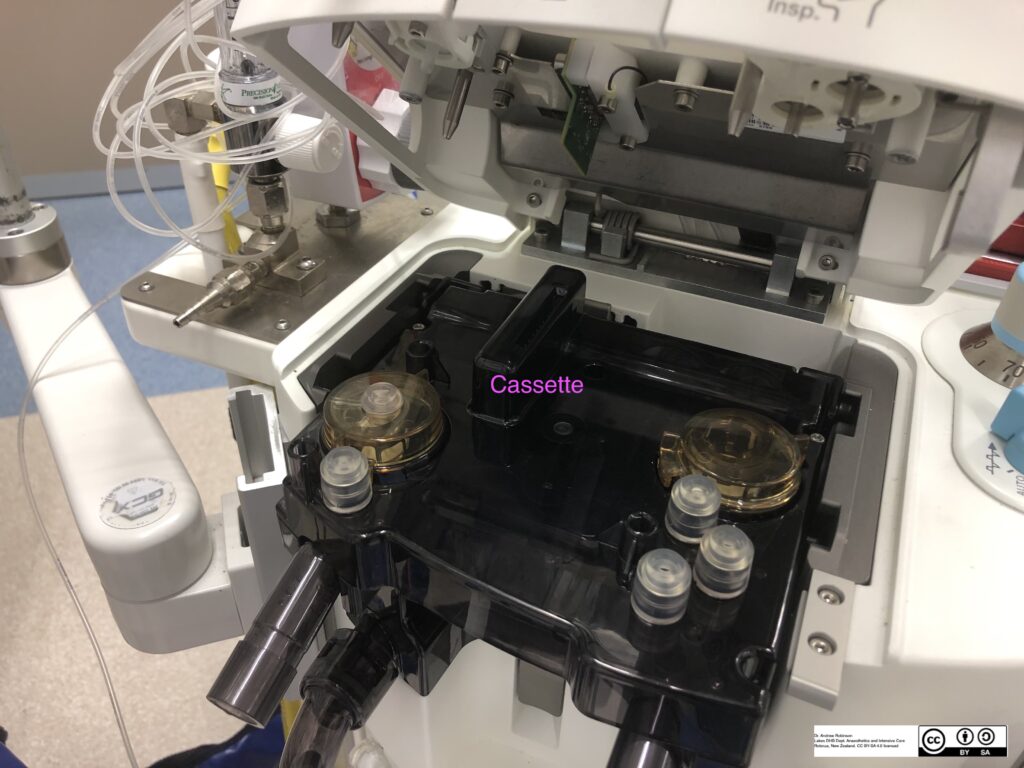

Prior to COVID-19 lockdown in New Zealand, we were approached by Kilwell Fibretube Engineering to assist in metal 3D printing a bridge part for an anaesthesia machine that was being converted to an intensive care ventilator.

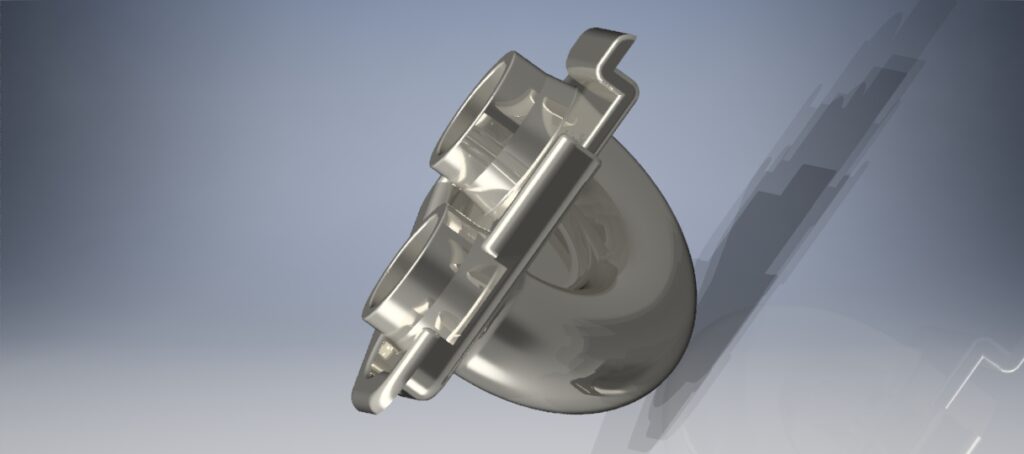

The successful prototype has a more simple design suited to metal 3D printing and it requires very little post processing. We have printed the bridges in Titanium 64 (a medical grade alloy) as this is our choice of powder for medical projects. They are quick to install and conversion only takes two minutes and that includes testing.

These Gettinge Group’s Maquet Flow-i anaesthesia machines are under-utilised in many hospitals world-wide and this endeavour could potentially increase the number of ventilated beds in Intensive Care Units (ICU). There are 7,000 of these Maquet Flow-i anaesthesia units installed globally and most of the machines are located in Europe.

RAM3D have a design that works and are currently scheduling in the print run to meet the demand in New Zealand.

Our design of the Bridge is going to be freely available in Europe. You can download the file here