Support is required for most metal 3D printed parts as it connects the part to the build plate. Support also holds up overhanging surfaces and helps maintain the structure. Surfaces below 45 degrees are likely to require support. Another use of support is to remove heat and stress build up within a part.

The ideal situation is where you only need a small support connection to the build plate to start the printing process and it would then build unsupported from there. However, in most cases, you will require support in some area of your parts. The key is knowing where to add it.

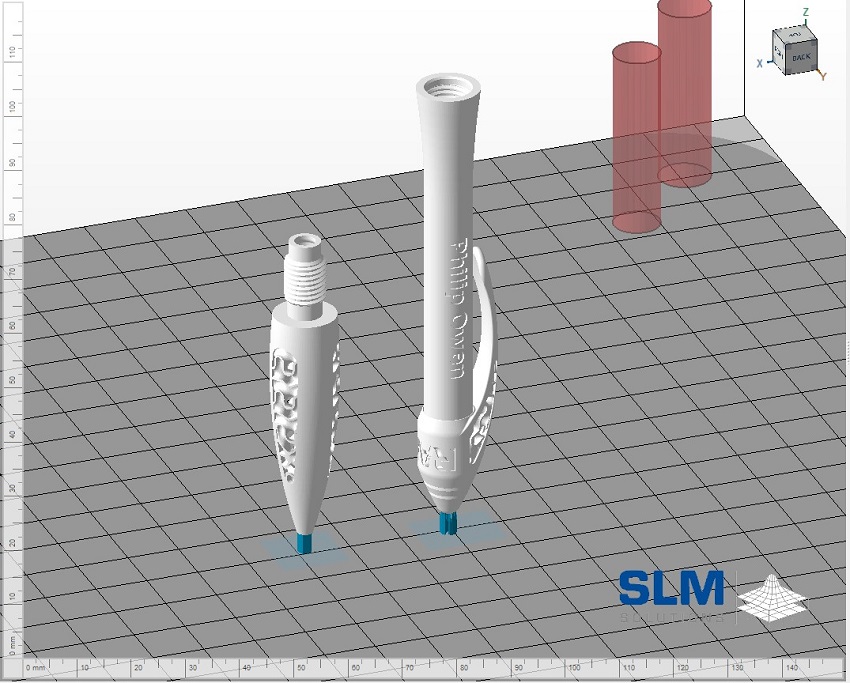

The example below shows two pen parts with the minimal support structure in place.

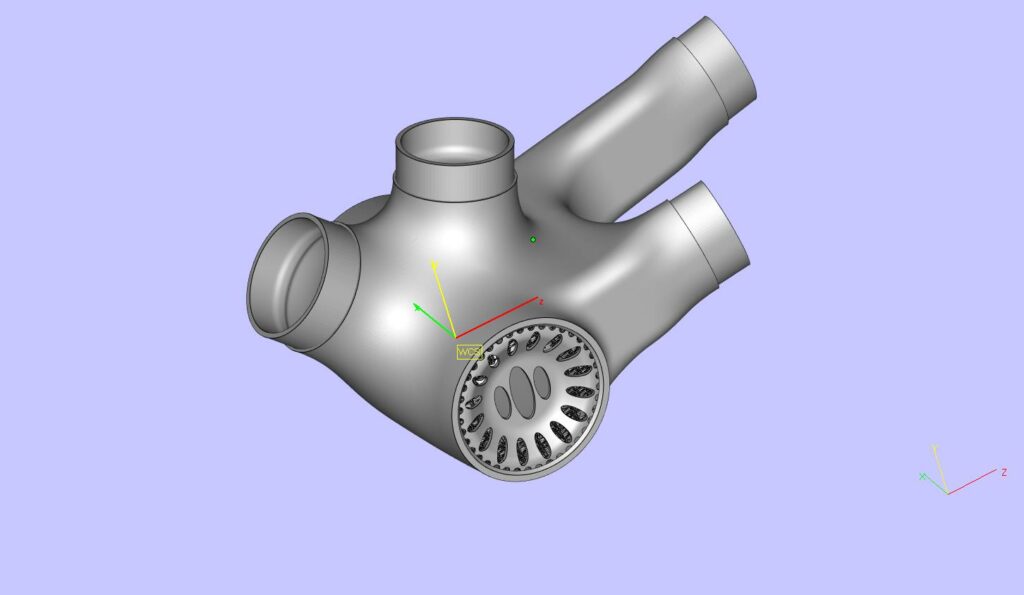

For parts that have large horizontal openings or where the shape is critical, it may be better to model in a sacrificial cap. We often use caps for post machined bearing surfaces to maintain concentricity, like the bike bottom bracket (below). If you do this correctly using a cap and lattice, you can use less material than if you had just used support structure.

The photos show, the latticed cap volume is 1350mm3 while the support volume is 2240mm3.

Another situation where you may need to model the support, is when a part could potentially spring open. This normally occurs on horse-shoe shaped parts during the build. Sometimes it’s better to tie these parts together and remove the ties after the build. Thin walled parts can also be supported by lattice structures to help stop warping and maintain shape. To do this, the lattice will need to be modelled as a solid and converted to a lattice. The lattice can then be removed if required.

Support structures that are added on using specific build software like Netfabb or Materialise Magics are easily removed via sacrificial teeth or break points. However, where the support meets the part, there will need to be some form of post processing. Our standard in house post processing uses die grinders (rotary burrs and grinding stones), linishing, sanding and media blasting. This can take away from the natural 3D printed look of the part and add cost due to material and time. So it pays to keep support in mind during the design of your part so you get the desired finish.